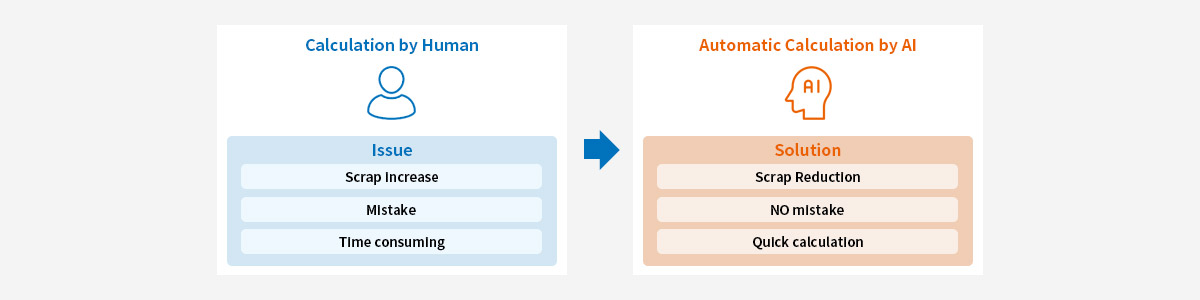

The coil center business has a long history and is an important business that supports manufacturing around the world.For this customer, the people in charge manually prepares slitting plan for tens of thousands of tons of coils per year, while they had following issues.

①Want to minimize the scrap loss amount

②Want to shorten the time for preparing slitting plan

③Want to stably achieve above①②, regardless of the skill level of the person in charge

Efficient analysis using mathematical optimization model reduced the amount of waste and shorten the time to prepare a slitting plan. Regardless of the skill level of the person in charge, customer were able to stably prepare the optimal slitting plan.

Specifically, based on the customer’s master coil inventory data and confirmed order data, the customer could prepare optimal slitting plan and reduce scrap loss amount equivalent to tens of millions of yen annually.

Customer were able to reduce the time required to prepare a slitting plan from over 30 minutes to just a few minutes.